What is a Melt Flow Index Tester?

A Melt Flow Index (MFI) Tester, also known as a Melt Flow Index Testing, is a laboratory instrument used to measure the flow rate of molten plastic materials. The flow rate is determined by extruding a polymer sample through a small die under specified conditions of temperature and pressure. The resulting measurement, the melt flow rate, is expressed in grams per 10 minutes (g/10 min).

This tool plays a vital role in the polymer industry as it helps determine the ease of flow of the molten polymer, which in turn provides insight into the material's viscosity and molecular weight. These properties are critical in defining the processing behavior of plastics and their final applications.

Why is Melt Flow Index Important?

The Melt Flow Index is a crucial parameter for several reasons:

- Processability: The MFI value gives manufacturers an understanding of how the polymer will behave during processing. A higher MFI indicates lower viscosity, meaning the material will flow more easily. This is particularly important in injection molding and extrusion processes, where the ease of material flow impacts cycle times and the quality of the final product.

- Material Selection: Different applications require plastics with specific flow characteristics. For instance, a polymer with a low MFI may be suitable for making strong, durable products, while a high MFI polymer might be chosen for applications requiring thin, detailed parts. By understanding the MFI, manufacturers can select the appropriate material for their needs.

- Quality Control: Regular testing of the MFI during production ensures that the material remains within the desired specifications. This consistency is crucial for maintaining product quality, reducing waste, and ensuring customer satisfaction.

- Predicting Mechanical Properties: The MFI can also be correlated with mechanical properties like tensile strength, impact resistance, and elongation at break. Understanding this relationship allows manufacturers to predict how changes in the MFI might impact the final product's performance.

How Does the Melt Flow Index Tester Work?

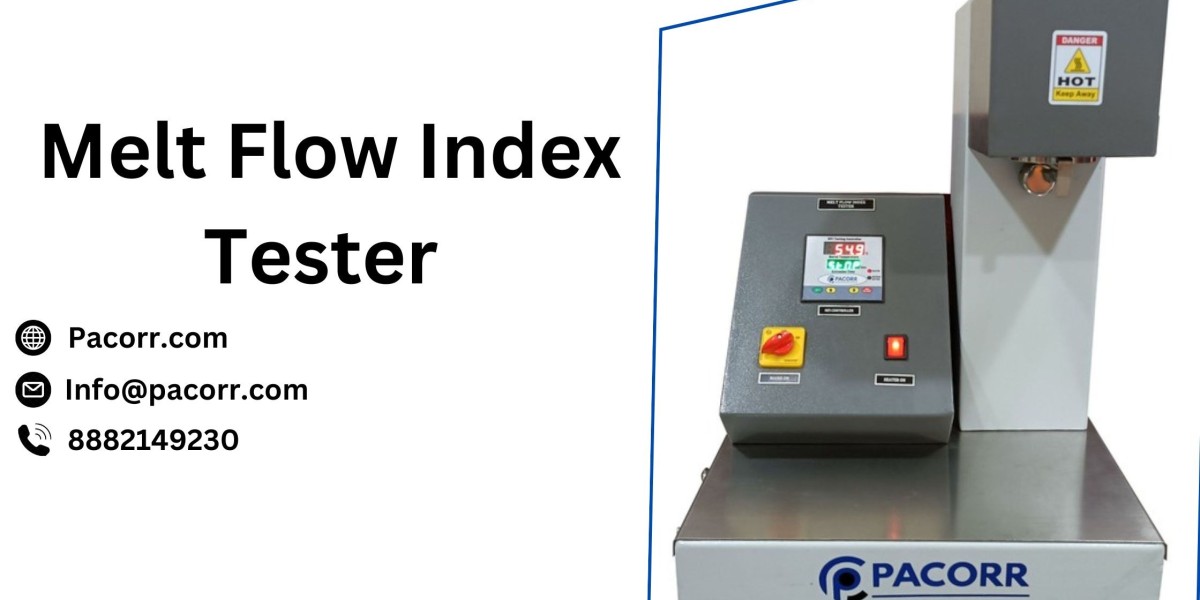

The operation of a Melt Flow Index Tester Price is relatively straightforward. A small amount of the polymer is placed into a heated barrel within the tester. Once the material reaches a specified temperature, a piston applies a standard load to push the molten polymer through a die at the bottom of the barrel.

The polymer extrudes through the die, and the amount that flows out in a set time (usually 10 minutes) is weighed to determine the MFI. The conditions under which this test is conducted—temperature, load, and die dimensions—are standardized to ensure repeatable and reliable results.

Applications of the Melt Flow Index Tester

The Melt Flow Teste is widely used in various industries, including:

- Automotive: Ensuring plastic components used in vehicles meet strict performance standards.

- Packaging: Evaluating the quality of materials used in packaging, from films to rigid containers.

- Medical Devices: Maintaining the reliability and safety of medical-grade plastics.

- Consumer Goods: Ensuring consistency in products like toys, electronics, and household items.

Choosing the Right Melt Flow Index Tester

When selecting a Melt Flow Index Tester, several factors need to be considered:

- Temperature Range: The tester should be capable of reaching the temperatures required for the polymers being tested.

- Load Options: Different polymers require different loads for testing; a good tester should offer a range of load options.

- Ease of Use: Automated features, such as pre-programmed test conditions and automatic sample cutting, can improve efficiency and reduce operator error.

- Compliance with Standards: Ensure the tester complies with international standards like ASTM D1238 or ISO 1133.

Conclusion

The Melt Flow Index Tester is an indispensable tool in the plastics industry, providing critical data that influences material selection, process optimization, and quality assurance. By understanding and utilizing this tool effectively, manufacturers can ensure that their products meet the highest standards of performance and reliability.

For more information on the Melt Flow Index Tester and other quality control instruments, visit Pacorr Testing Instruments.